We use state-of-the-art test methods and apply our extensive experience to make rail transport safe, reliable and profitable. Thanks to our services, our clients save time and money in maintaining the long-term reliability and performance of their rail networks.

OUR SERVICES

Visual inspection

Our employees are trained and, above all, highly experienced in visual inspections. Expert visual inspections ensure that mechanical damage (caused by rolling contact, for example), manufacturing defects and assembly-related workmanship defects are clearly identified and thoroughly assessed. Even when other testing methods are also deployed – a visual inspection always comes first.

Ultrasonic testing

We use ultrasonic testing to detect track defects in real time, from internal irregularities to corrosion of the rail foot. We work with state-of-the-art hand-guided track testing devices to detect and assess irregularities in tracks and switches caused by defects in workmanship, manufacturing or operation. We are also able to conduct surrogate measurements for rail testing vehicles. Once a rail testing vehicle has detected irregularities, these must be investigated further. We do this by means of ultrasonic damage assessments in accordance with DB Guideline 821.2007. We also offer manual ultrasonic testing for assessment and documentation purposes and are happy to provide clients with a proposal for cost-effective maintenance, if required.

Eddy current testing

We use eddy current testing to detect surface defects. This method complements ultrasonic testing of both tracks and switches: Head check defects develop gradually due to fatigue caused by rolling contact – a problem that occurs throughout rail networks. Eddy current testing is imperative once a head check defect has been detected visually. We perform this test reliably and economically using our modern eddy current testing equipment.

Magnetic particle testing

Magnetic particle testing serves to detect and confirm surface cracks in components. When large switch assemblies and rails are reconditioned, magnetic particle testing should be conducted immediately after defects have been rectified. This step is essential for confirming that the material is free from cracks before performing build-up or overlay welding. It therefore has a decisive effect on quality.

Engineering services

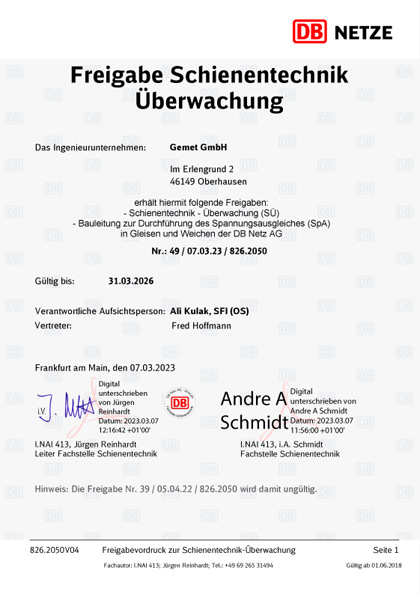

Rail technology monitoring

We monitor the production of continuous welded rails and welding works in switches and provide geometric acceptance of welded joints in switches and tracks. We provide technical consultation on welding works and supervise construction.

De-stressing supervision

We supervise de-stressing works in the production of continuous welded rails and provide subsequent documentation.

Quality control of track treatments

We offer quality assurance for track treatments by qualified employees.

Construction supervision

We supervise track works, also in conjunction with welding works.

“Rail systems are super complex. My work forms part of a larger whole, and I’m proud to know that what I do helps ensure that your passengers reach their destinations safely. After all, safety can be put to the test.”

Fabian Knorre

A glimpse of our work

Certifications